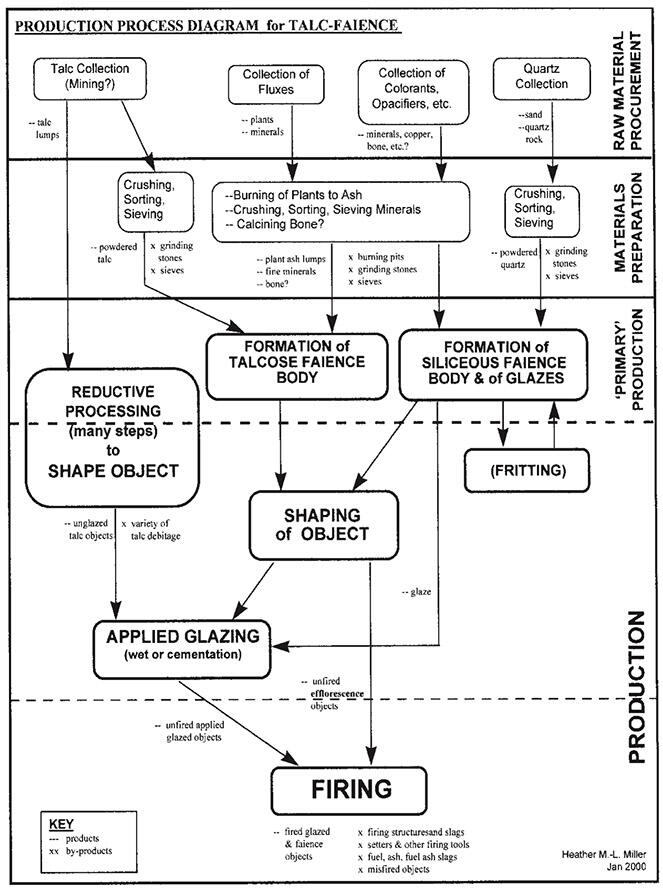

"Talcose stone was used primarily to make beads, seals and tokens, but also for inlay pieces, small figurines and sculptures. In contrast to faience, massive talc was not commonly used to produce either small vessels or bangles. Massive talc was also sometimes glazed, particularly the beads, usually with a blue-green colour. There is increasing evidence that Indus talcose objects were glazed more often than generally thought, as the glaze often breaks down during the thousands of years of burial, leaving only trace amounts (Barthélémy de Saizieu and Bouquillon 1997)" writes the author in this highly informative survey (p. 113). "Talcose stone material," whether as paste, powder, fine or coarse-grained was a mineral that play a key role in Indus society, subject to complex manufacturing processes at which the Indus people clearly excelled and the author lays out in a way that only makes us wonder, yet again, at their sophistication and innovation (incidentally, she notes that few misglazed and misfired objects were found despite the high volume of manufacture). Note the diagram above which lays out the steps involved in manufacture.

To make things even more complicated, Miller also notes that "there is increasing evidence that Indus talcose objects were glazed more often than generally thought, as the glaze often breaks down during the thousands of years of burial, leaving only trace amounts (Barthélémy de Saizieu and Bouquillon 1997)" (p. 113). Furthermore, "a major challenge for the artisan was insuring the correct binding of the glaze to the body, both before and after firing. The wet glaze had to sufficiently adhere to the body and not drip off, but not be absorbed into the body completely on drying. The fired glaze had to be sufficiently bound to the body so it did not flake off, but excessive shrinkage of the glaze had to be avoided or the glaze would crack or craze. The glaze composition and / or the firing regime would have had to be somewhat different for each body, and for each of the three primary methods of glazing: wet applied glaze, cementation and efflorescence" (p. 115).

The paper discusses numerous aspects around the aptly-named "talc-faience complex," including puzzles like the presence of bone materials in "slag" (firing materials) at Harappa and Mohenjo-daro. A highly-recommended, judicious look into a key nexus of Indus civilization.

Image: 1. Hundreds of unfinished steatite beads were found in one small area an ashy floor in Trench 54, Harappa. 2. Outline of production processes for the talc-faience complex.