"The discovery of the rotational capabilities of the wheel was one of the most significant human inventions, and wheel-enhanced rotation is now pervasive in the tools and machines that we use in our everyday lives. Importantly, the wheel was a major contributor to a range of developments in craft production technology, perhaps most visibly in the various forms of potter’s rotational devices and wheels." So write the authors (p. 1) introducing this in-depth look and recent research in ceramic manufacturing techniques at two ancient Indus sites in Haryana, India, Lohari Ragho I and Masudpur I. While they are concerned with the specific means used for manufacturing different pottery vessels at these sites and what this might say about the makers themselves, they are also invested in looking at the larger debate about how wheel-throwing and wheel-fashioning were used in Indus and wider traditions. The former refers to the use of a fast wheel as a major potters manufacturing device, the latter to a more "partial use of rotational devices for wheel-fashioning and wheel-finishing techniques [which] was dominant in the Indo-Iranian region, associated with other forming techniques such as coil- building, wheel-coiling, moulding, beating, and paddle-and-anvil" (p. 3). According to the authors, the former is a also implies a more techno-deterministic model, "a linear evolution in the use of wheel- throwing techniques and the fast wheel in prehistory," while the latter suggests "a more complex process of technological innovation and a non-linear trajectory of adopting rotational devices" (p. 4). Either way, evidence from sites in the Middle East and Mediterranean suggest that the overlap and adoption of different technological methods by different potters during the Bronze Age was uneven.

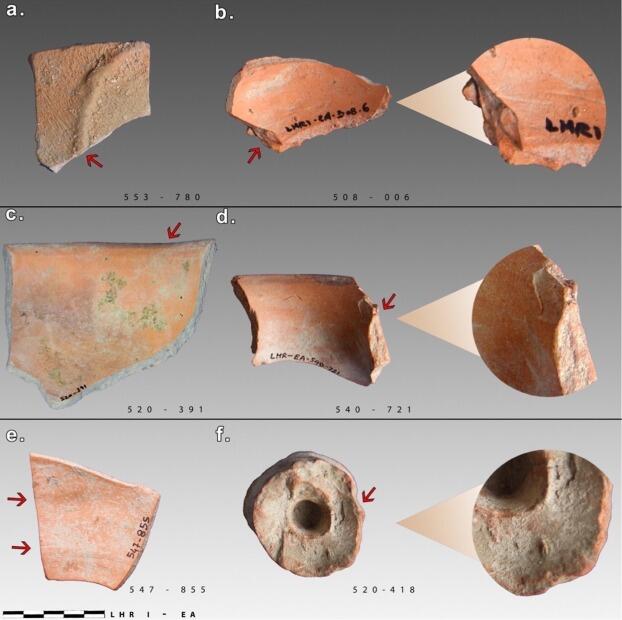

While this paper does not settle the debate, it does open a fascinating light on how looking carefully at the manufacturing sequence as disclosed by microscopic analysis of pottery vessels and fragments illuminates different manufacturing techniques. These in turn speak to different methods being employed by what must be different communities of makers, even at the same site and time. The clues on pottery, the "rotational gestures" that can be decoded from a close reading of the sherds allow archaeologists to infer much about the manufacturing processes. The beautiful images in the article show how the tiniest set of lines, if not scratches, can be used to deduce information about the maker's technique in making the vessel; in this analysis, over 600 sherds were analyzed from two recently excavated sites.

The analysis, in the end, suggests that two somewhat different traditions and tactical strategies were were involved in manufacturing the same type of vessels at both sites, what the authors group into "Indus Masudpur-Lohari A" and "Indus Masudpur-Lohari B" traditions. The second "were defined by a combination of sophisticated forming techniques and high control during the manufacturing process, including preliminary coiling and marks associated to abundant use of rotational gestures or devices." This resulted in vessels "possibly the most evocative of a regional Indus flavour" (p. 9). They conclude that "different ceramic forming methods were practised during the third millennium BC in northwest India.

The rediscovery of these variable practices has a range of implications, and it is likely that the diversity of forming methods corresponds to different technological and cultural behaviours, and can be used to explore ancient social structures. The identification of diverse forming and finishing techniques improve understanding of the development of technological traditions, but also the reasons behind diversification, innovations and resistance to innovations of certain communities of producers, including the possible development or adoption of the potter’s wheel" (p.9). Most importantly "the identification of two distinct ceramic traditions at LHR-I and MSD-I suggests the presence of distinctive communities of producers, or potentially different social units, within and/or around these settlements" (p. 11).

A sophisticated, fascinating analysis that once again reminds us how diverse and varied ancient practices were. Modern archaeologists are just beginning to scratch at the many approaches people once may have taken to the same tasks.

Image: Evidence for the use of coils at various stages of ceramic production on sherds from Lohari Ragho I Trench EA. Arrows point to macroscopic features that could be used to determine the use of forming methods, including the possible use of coils (e.g. breakage patterns, surface topography, and coil joints). Sherds from LHR-EA: a: 553–780; b: 508–006; c: 520–391; d: 540–72; e:547–855; f: 520–418.